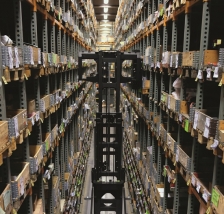

BT Vecto R-Series Narrow aisle trucks Developed on the bases of richtrack have

to have the operator's compartment installed below. This equipment is designed

for work in very narrow aisles. These narrow aisle trucks may be equipped with

conventional or extension type forks, which need less space and provide

high-speed cross traverse movement of pallets. The narrow aisle trucks movement is

controlled by rail guides or induction wire enabling fast and safe work in very

narrow aisles. The model range with load capacity from

1.25 and up to 1.5 tons provides handling of loads at height of 11.3 meters.

Specifications

| Model | Capacity, kg | Lifting height up , m | Aisle width, mm | |

|---|---|---|---|---|

| VRE125SF | 1250 | 11.3 | 1450 | Check the price |

| VRE125 | 1250 | 6.7 | 1660 | Check the price |

| VRE150 | 1500 | 11 | 1660 | Check the price |

Features of VRE125SF/VRE125/VRE150 models,

BT Vector R-series:

- VRE125 and VRE150 models are equipped with a traditional fork with a swinging head; VRE125SF model is equipped with the extendable fork of a shuttle type for a quick lateral handling with pallets within the narrowest working passages

- Operational parametres of the stacker can be fully programmed (running speed, speedup, etc.) and adapted as per each operator’s requirements, saving the settings through the use of a pin-code which shall hinder other operators to alter saved data

- Ergonomic operator's spot with a convenient and adjustable seat

- Operator's cabin is equipped with a protective grating and provides excellent visibility

- The option of the control system with a video camera mounted on the fork facilitates operation with pallets at high altitudes

- The availability of Transitional Lift Control (TLC) system provides very smooth lifting or lowering of the cargo at the maximum speed

The standard provides installation of the additional equipment: computer, scanner, keyboard, etc. while the excellent visibility is not affected. The choice of various widths and lengths of chassis allows determining the necessary configuration of the stacker for each particular place of operation.